Error: Contact form not found.

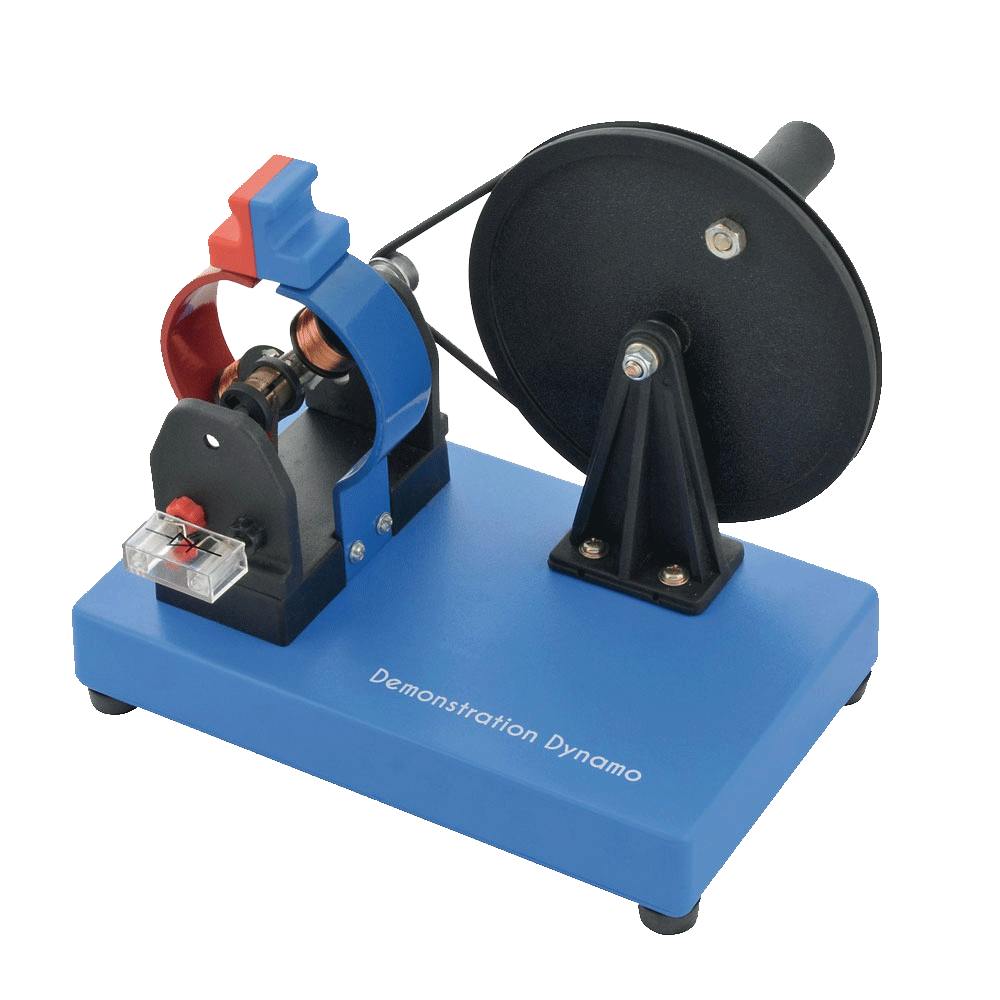

Shell Tube Heat Exchanger Water To Water

Heat exchanger is the devices used to transfer the heat from one fluid to other. The shell and tube heat exchanger is two tube single pass heat exchanger. The hot fluid is hot water obtained from water heater. The coil fluid is cold water. The schematic flow arrangement is shown in figure. Hot water enters the lower side of end box, flows through the tubes in lower half of shell and comes to the other end of the shell. It reverses its direction, flows through tubes in upper half of the shell and leaves out. Cold water enters lower part of the shell passes over the tubes between the baffles and leaves out the shell through outlet at upper surface of shell.

SPECIFICATIONS:

1.Shell – 150NB, 750 m.m. long provided with end boxes. a.One end box with divider plate. b.25% cut baffles – 4 Nos. in the shell. 2.Tubes – 4.5mm I.D., 6.35mm O.D.,250 m.m. length copper tubes with triangular pitch. 3.Instantaneous water heater, 3 Kw capacity, to supply hot water. 4.Thermometer for measuring the water temperature. 5.Valves to control hot and cold water flow.SERVICES REQUIRED:

1.3 P H, AC supply 2.Floor space 1.5m. X 1m, 3.230V, 15A, AC supply with earthing connection. 4.Water supply at the rate of about 10 lit/min at constant heat.Specific Heat Of Air Apparatus

The apparatus consists of heating element on which the air is blown. The difference in temperature of air is shown by the temperature indicator. The flow of air is measured by the orifice meter. The input to the heater is measured by voltmeter and ammeter. Thus the specific heat of air can be found out.

SPECIFICATIONS:

1.Air blower connected to FHP motor. 2.Orifice meter to measure the air flow, Heater – 1 KW heating coil placed centrally in the test section. 3.Multi channel digital temperature indicator – range 0 to 300 c. 4.Voltmeter and ammeter to measure the heat Input.SERVICES REQUIRED:

1.220 volts single phase stabilized AC Electric supply. 2.Floor space – 2 m. X 1 m. X 2 m. Height.Stefan Boltzmans Apparatus

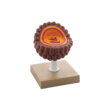

The Stefan Boltzmann constant is an important constant in heat transfer. The apparatus determines Stefan Boltzmann constant. The apparatus consists of a hemisphere surrounded by hot water. Hot water is obtained from a water-heating tank. When the blackened disc is inserted at the center of hemisphere, heat is transferred into the disc from hemisphere by radiation and its temperature begins to rise, and from temperature raise rate. (It is measured at the intervals of 5 sec.) Stefan Boltzmann constant is determined.

SPECIFICATIONS:

Water heating tank provided with electric immersion heater. Hemisphere made of copper sheet, 200mm. dia. Surrounded water jacket of 250mm. Dia. Test disc made of copper 20mm. dia. provided with thermocouple at the center. Multichannel digital temperature indicator 0-200 C with 0.1C least counts to measure the temperature of hemisphere and disc. Audible buzzer with timer to ring at every 5 seconds. A technical manual accompanies the unit.SERVICES REQUIRED:

1.Bench area of about 1m. x 05m. at working height. 2.230v, 15A, AC, electric supply with earthing connectionTheramal Conductivity Of Insulating Slabs

The apparatus consists of a slab assembly. The main Heater and a radial guard heater are sandwiched between copper plates. The specimen in the form of slabs of equal thickness are placed on either sides of heaters and cooling plates through which water is circulated are on the other Sides of the specimen. The radial guard heater ensures all heat of the main heater to pass axially through the specimens which is collected by cooling plates. By knowing the temperatures and Heat input, thermal conductivity of specimen can be calculated. The test set up is enclosed in an enclosure with insulation inside to provide undisturbed Surroundings. The design style of the apparatus is similar to as recommended in INDIAN standard. The difference is in sizes.

SPECIFICATIONS:

1.Heaters: a)Main heater plate 110 mm dia. with mica heater Sandwiched between copper plates. b)Radial guard heater plate I.D. 120mm and OD 200 mm mica heater sandwiched between copper plates. 2.Water circulated cooling plates -2 nos. 3.Dimmerstat-2 A capacity – 2 nos. to independently control Inputs to the heaters. 4.Measurements – A voltmeter and an Ammeter with selector switches to measure inputs,Multichannel digital temperature indicator to measure Temperatures at various points, having 0.1 °c least count. A technical manual accompanies the unit.SERVICES REQUIRED:

1.230 V, A.C. stabilized supply along with earthing connection. 2.Water supply of about 4-5 lit/min. 3.Bench area 1m x lm x O.5m height.Thermal Conductivity Of Insulating Powder

The apparatus consists of an insulating powder, which is enclosed in a cavity of two concentric spheres. The inner space of the inner sphere contains the mica heater. Input to the heater can be adjusted by the dimmerstat. The tappings on the surfaces of the inner sphere and outer sphere are used to find out the temperature difference between the spheres. This enables to find out the conductivity of powder.

Specifications:

1.Inner sphere dia. 100mm and outer sphere dia. 200mm. 2.Mica heater two heat the inner sphere surface. 3.Ten thermocouple tappings in the test section. 4.Plaster of Paris / asbestos powder in the test section. 5.Panel comprises of a)Voltmeter and ammeter b)Dimmerstat c)Temperature indicatorServices required:

1.220v stabilized single-phase supply. 2.Floor surface 1m x 0.5m at working height.Thermal Conductivity Of Liquid

Thermal conductivity of is an important engineering property. The apparatus uses guarded hot plate method for determining thermal conductivity. It consists of hot plate i.e. an electrical heater sandwiched between two plates. The heat loss from hot plate is prevented by using two guard heaters and heat of removes heat from liquid by circulation of water. Input to heaters the temperatures.

SPECIFICATIONS:

1.Guarded hot plate assembly comprising of main heater, ring guard heater and top guard heater, mounted over the liquid test cavity. 2.Cold plate assembly provided with water connections. 3.The assembly is housed in an enclosure box with glass wool insulation. 4.Instruments panel consisting of : a).Digital voltmeter and ammeter of suitable range. b).Dimmerstat for controlling input to the heaters (2 amp. 3 Nos.) c).Multichannel digital temperature indicator.SERVICES REQUIRED:

1.Floor space of about 0.75m. x 1.5m. at working height. 2.230v. AC electrical supply with earthling connection. 3.Water flow rate of about 10- 15 lit/min. at constant head.Thermal Conductivity Of Metal Rod

The apparatus consists of a copper bar, which is heated at one end, a heat sink is provided at other end. The test section of bar is properly insulated and thermocouples are attached along the length of bar. Heat conducted through the section of bar is measured by heat collection in water-cooled heat sink. A panel comprising of controls and measurements is provided, which provides easy operation and sturdy mounting of unit.

SPECIFICATIONS:

1.Metal Bar – 25mm of adequate length, provided with 8 Thermocouples along the length, Band heater at one end and water-cooled heat sink at other end. Test portion of bar is insulated. 2.Instruments panel comprising of. Voltmeter … 1No. Ammeter … 1No. Dimmerstat 0-230v, 2A, capacity. Multichannel Digital temperature Indicator. 3.Measuring flask and stop clockSERVICES REQUIRED:

1.Bench area of 1.5m. x 1m. at working height. 2.230 v, AC, electric supply with earthing connection. 3.Water supply at the rate of 2 lit/mmThermocouple Calibration Test Rig

The Unit helps in calibrating given thermocouple for the range 0°C to 100°C. While calibrating, thermocouple is once dipped in ice for 0Q C and then in boiling water for 100°C. This is done till the thermocouple shows the actual temperature of ice (0° C) and boiling wafer (100°C) and a linear calibration is set. A mV meter is provided to know the corresponding voltage.