Error: Contact form not found.

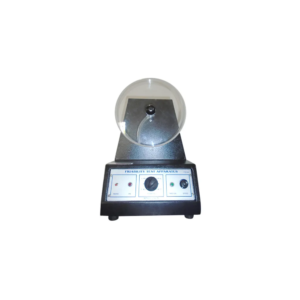

Sieve Shaker (Gyratory Motion)

Ensuring durability during performance, this machine is made of mild steel and cast iron and comes with one Lid and a Pan.

This unit is used with up to 7 sieves of 150mm or 200mm (8 Inch) sieves and up to 6 sieves of 300 mm (12 Inch).

Heavy duty motor (1/4 HP) ensures the whole performance through a reduction gear immersed in oil.

Along with featuring gyratory motion, this units also performs upward and downward movement ensuring that each "square cm" of the sieve is fully utilized.

This Gyratory Sieve Machine also supplied with a pair of rods and a holder which ensures tight grip of sieve set from the top.

| Product: | Gyratory Sieve Shaker | |

| Capacity: | 7 sieves of 150mm, 6 sieves of 300mm | |

| Design: | Table Top | |

| Construction: | Cast Iron, Painted Mild steel | |

| Motor: | ¼ HP | |

| Timer: | 0 - 60 Minutes | |

| Timer Type: | Digital / Analog | |

| Power Supply: | 220 Volts |

Sieve Shaker (Hand Operated)

Sieve Shaker Electrical Table Model (Only For 8” Dia Sieve)

Sieve shakers are used to measure particle size as part of your research or quality control applications.

Sieve shakers provide uniform motion to ensure the reproducible results you can’t get from hand sieving. Electrically operated Fitted with Electric Motor inside the Body having speed regulator to increase of discrease the vibration. The table sieve shaker having the capacity of 8 Sieves.

Sonicator

Description

Ultrasonics (Ultrasound) is the sound which human beings cannot hear. Ultrasound utilizes frequencies from and above 18khz (18,000 cycles per sound) High frequency electrical energy is converted into ultrasound waves by means of ultrasonic Transducers, which are bonded on the base of S. Cleaning Tank. These high frequency sound waves create in the liquid countless, Microscopic vacuum Bubbles which rapidly expand and collapse.Features

Easy to operates & maintain with one piece S.S. Tank. Digital Tuning of Transducers with Generators to avoid any frequency shifted even during demanding applications. Compact, rugged and highly durable systems. Extensively protected electronic circuits means longer and safer Operations.Specifications

Operating frequency 33 -3KHz, for all general purpose cleaning is highly recommended Input Voltage range of 170V AC- 270V AC, 50 Hz, Single phase Micro Controller based timer range 0 to 30/99 minutes. Thermostatic controlled temperature controller. (Ultra Sonic Bath),Complete S.S & Digital Temp.Controlled Capacity 2 Ltr Approx Capacity 3 Ltr Approx Capacity 6 Ltr ApproxSpirometer

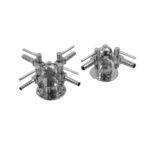

Sterility Test Apparatus (S.S Manifold)

It consists of Stainless steel holders in the manifold of 3 of 6 to hold 47 mm dia membrane filters, the tops of the holders are connected to the outlets of flushing tube with silicone tubing and glass top cock.

A vacuum resistant flask or wolf bottle must be placed between the manifold and vacuum pump.

(Supplied without wolf bottle and vacuum/pressure pump).

These units are used for sterility testing when the membranes filter is to be removed from the holder for incubation in culture media.

Filtration area is 12.5 cm and has a holding capacity of 250ml.

Though the only vacuum is required for filtration, some pressure is required for flushing liquids.

SPECIFICATIONS

| Material: | Stainless Steel | |

| Branch Test: | 3 Dia. 47mm | |

| Filtration Area: | 12.5 cm | |

| Holding Capacity: | 250 ml |

FEATURES

Robust design. Easy to use. Rustproof.APPLICATION

For microbiology, biochemistry, hydrobiology (DNA/RNA). Beverage analysis & food testing. Protein binding, gravimetric analysis, coliform, yeast, mould total bacteria & sterility testing. Ideal for water & wastewater analysis. Residue precipitate analysis and contamination tests. General Liquid Filtration.Single Test (Filter Holder S.S) Three TestStudent Organ Bath

We offer an impeccable range of Organ Bath to our prestigious clients.

Our entire range is by keeping in mind the latest market trends using optimum quality raw material and cutting-edge technology in line with set industry standards.

This product is well-known in the market for its remarkable features like easy installation, durability and best quality.

Furthermore, clients can avail this product from at industry leading prices within stipulated time frame.

Features

Single & double unity organ bath Durable body structure High efficiency Hassle free performanceSuppository Mould

Table Counter Suitable for 100 tablet

Tablet Coating Pan

Product Description

We offer coating pan that is designed to perfection and fabricated from best grades of raw material procured from reliable sources. These coating pan are suitable for coating tablets and is checked by our quality controllers for high performance and uniform coating all over the tablet. The different parts of our coating pan machines are listed as under:PAN

The coating pan is SS semi ellipsoidal size pan with a circular mouth for charging & discharging of tablets, Pan mounted at an inclination of 45 degrees to the horizontal.DRIVE ASSEMBLYPAN

The tablet coating pan consists of a suitable HP 3 Phase, 440 V, 1440 RPM TEFC motor with suitable worm reduction gear box and cone pulley arrangement to give three speed output.HOT AIR BLOWERPAN

The tablet coating pan unit is provided with a hot air blower consisting of suitable HP 3 Phase 440 V, 2880 RPM TEFC electric motor & centrifugal blower with damper delivering required CFM. The air is heated by means of suitable electric heater to give air at 30 to 90 degrees Heater with thermostat control and flexible hose pipe.Tablet Friability Test Apparatus

Digital Friability test apparatus is microprocessor based instrument designed to monitor the resistance of tablets to stresses and to decide their suitability for the further processes.

A fix 25 RPM Motor drives the unique Universal acrylic drum(same drum can be used at left or right side of the instrument).

Digital microprocessor based counter is provided to pre-set the revolution & to automatically stop the motor with alarm.

These features eliminate the tedious calculation of timer mode.

In Power failure, the memory of the microprocessor remembers the tie left and complete the cycle after power resumes.

Easy loading and unloading of the drum with positive grip is provided.

Unloading of the drum after every test is required to remove the traces of loose dust on the drum for accurate calculation of friability.