XTEMOS ELEMENT

AJAX PRODUCTS TABS

Bone Cutters

Rheostat, Protected With Single tube

Leak Test Apparatus (S.S BODY)

Ideal instrument to check blister Packs, Strip for Leak Test.

The old method of separate desiccator and the huge vacuum pump is replaced with the new Leak Test Apparatus in GMP Stainless Steel Body with phenomenal compactness.

The instrument is equipped with Diaphragm type vacuum pump gives the higher level of vacuum in shortest possible time.

Die pressed polycarbonate vacuum desiccator sustains vacuum for a long time.

A vacuum gauge is provided to indicate vacuum level which is connected to isolation valve to disconnect the source.

Thus avoiding the need of continues running of the vacuum pump.

| Body: | Stainless steel. 304 | |

| Desiccator: | SPolycarbonate, 8” Desicator Provided with Digital Timer | |

| Timer: | S3999 sec. Digital | |

| Vacuum Level: | S 22" Hg | |

| Current: | S 5A | |

| Voltage: | S 230 |

XTEMOS ELEMENT

AJAX PRODUCTS TABS SIMPLE

Hydraulic Ram Test Setup

DESCRIPTION:

The Set-up is designed to study the Hydraulic Ram. Hydraulic RAM is used for pump little quantity of water to high head from a large quantity of water available at low head. It works on a principle of water hammer stating that “When flowing water is suddenly stopped in a long pipe a pressure wave travels along the pipe creating an effect of water hammer”. The Set-up consists of a pipe section fitted with a pulse valve and non-return valve, a supply reservoir on a stand which is connected to an overhead tank, an air vessel above the valve chamber smoothes cyclic fluctuations from the Ram delivery. Different pressure may be applied to the pulse valve to change the closing pressure and hence the operating characteristic. The flow rate of useful and waste water is measured using measuring tank and stop watch provided. Pressure and Vacuum Gauge are connected on delivery and suction side for the purpose of measurement.EXPERIMENT:

Ø To find out discharge of useful water and waste water. Ø To find out the efficiency of the Hydraulic RAMFEATURES:

Ø Closed loop water circulation Ø Compact & stand alone set-up Ø MS Excel sample calculation program on demand Ø Stainless Steel tanks and wetted parts Ø Superb painted structure Ø Simple to Operate & MaintainUTILITIES REQUIRED:

Electric Supply: – Provide 230 +/- 10 VAC, 50 Hz, Single Phase Electric Supply with proper earthing. (Neutral – Earth voltage less than 5 VAC) 5 A, three pin socket with switch for pump. Water Supply: Tap water connection ½ “ BSP Distilled water @ 90 Ltrs. (Optional)TECHNICAL SPECIFICATIONS:

Ø Product : Hydraulic RAM Ø RAM : Size 50 x 15 mm, Supply Head 2.5m, Delivery Head 10 m (max.) Ø Air Vessel : Suitable Capacity MOC SS Ø Delivery Line : For RAM, Dia 50 mm Length 6 m. Ø Pump : Capacity 1 HP, Crompton / Sharp / Hero make Ø Supply Tank : Capacity 150 Ltrs. Ø Overhead Tank : Capacity 100 Ltrs. Ø Measuring Tank : Suitable Capacity one each for useful and waste MOC SS fitted (2 Nos.) with Piezometer Tube & Scale Ø Piping : GI / PVC Ø Stop Watch : Electronic Ø Pressure Gauge : Bourdon Type Ø Control Panel : Comprises of Standard make On/Off Switch, Mains Indicator etc. Ø Tanks will be made of Stainless Steel. Ø The whole Set-up is well designed and arranged in a good quality painted structure.Earth, Neutral And Live Board Demonstration

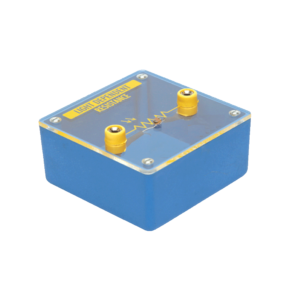

Description

This apparatus is an effective demonstration of how the earth wire and fuse act together to protect both the user and the appliance. When the appliance is connected correctly and the LEDs in the appliance will illuminate to show the appliance is working. A fault is then demonstrated by swapping the live wire from inside the appliance to the case to show either the fuse melts (protecting the user and appliance) or in the case of no earth wire, the LEDs illuminate to indicate the passage of current through the person to ground. The fuse is easily visible and can be seen to ‘blow’ when a fault occurs.The unit is supplied with 10 m of fuse wire and full instructions. A 12 V DC power supply is required. Connections are made via 4 mm shrouded sockets.XTEMOS ELEMENT

AJAX PRODUCTS TABS ALTERNATIVE

Fashion

Polariser and Analyser (Polaroid)

Electronic Total Station

Electronic Ignition System Of An Automobile

XTEMOS ELEMENT

AJAX PRODUCTS TABS ARROWS PAGINATION

Epicyclic Gear Train Holding Torque Apparatus

It is a motorized unit consisting of SUN gear mounted on input shaft. Two plane gears mesh with the annular gear. These planet gears are mounted on a common arm to which output shaft is fitted. Loading arrangement is provided for loading the system and to measure Holding Torque.

Specifications:

1. External type Epicyclic Gear Train: a. Bearing blocks for input & output shafts. b. A gear train with Holding drum and handle. 2. Internal Type Epicyclic Gear Train: a. A compact Gear Train. b. Variable speed D.C. Motor c. Rope brake arrangement to measure output torque and holding torque. 3 Control Panel comprising of a. Digital Ammeter and Voltmeter. b. RPM Indicator. c. Speed Controller.Experimentation –

1. To measure epicyclical gear ratio between Input shaft and Output shaft. 2. To measure epicyclical gear ratio between Input shaft and holding drum. 3. To measure Input torque, Holding torque and Output torque.Service Required –

1. Floor Space – about 1.5m x 2m. 2. 230 V.AC stabilized power supply.Analog PID Controller

The analog PID controller is a special purpose analog controller with operational amplifiers The controller permits a detailed analysis of the application of proportional, integral and derivative control to the improvement of their performance. The controller may be used at high speed for oscilloscope observation or at a low speed for meter observation.

FEATURES:

• Two analog meters (centre zero meters) to display the set variable and process variable. • In built regulated power supply. • Provision to vary and measure the setpoint (0-5)V • Provision to vary the proportional gain, Integral time and derivative gain. • Provision to give either (4-20)mA or (0-5)V externally as a process variable. • Provision to select the controller output as (4-20)mA or (0-5)V internally. • All the components are mounted in an attractive cabinet. • Interface with any realtime process (Level, Flow, Temperature, Pressure, DC motor speed control etc.,)Stereo Microscope

Specifications

| Objective Lens | : | 1x & 2x. | |

| Eyepiece Lens | : | WF 10x/20mm (or 15x on request) (Paired) | |

| Magnification | : | 10x or 20x (15x or 30x with 15x eye piece) |

XTEMOS ELEMENT

AJAX PRODUCTS TABS WITH ICONS

Calorimeter, Electric

Car Chassis Rear Wheel Drive Actual Cut Section Motorised

Car Chassis Rear Wheel Drive Actual Cut Section – Motorised

4 Stroke 4 Cylinder Petrol Engine With Clutch, Gear Box, Propeller Shaft, & Rear Axle Assembly With Differential Gear

The chassis of the four stroke four cylinder engine cut section model. The cut section model is constructed such that all the following systems can be demonstrated in working conditions.

ENGINE:

Maximum parts and accessories of an engine like cylinders, cylinder head, inlet and Exhaust manifolds, FIP, injectors, self-starter, alternator, water pump, radiator, etc., are sectioned to show the internal constructional details. The complete sectioned model is coupled with FHP 220/230V A.C single phase motor through a Reduction drive unit.TRANSMISSION SYSTEM:

This system consists of a Clutch and four speed gearbox assembly, the casing of which is suitably cut to demonstrate its operation. The gearbox is coupled to Differential gear box with propeller shaft and the different coupling used for this transmission can be demonstrated. The Differential gear box is also cut so as to clearly to demonstrate its complete operating principle. The gear shifting including the forward and reverse gear operation can be clearly shown. The speed variation and the rotation of the Differential gear box can be seen while gear shifting. By running the motor connected to the engine assembly the entire system with gear box, rear axle etc. can be demonstrated in running. FUEL SYSTEM: The Fuel tank is cut to expose the mounting of the level sensor and the position of Fuel section. The system is complete with mechanical Fuel pump. EXHAUST SYSTEM: It consists of Exhaust Manifold and silencer in cut section to explain internal construction. LUBRICATION SYSTEM: It consists of the engine Lubrication system along with the Lubrication oil pump is suitably sectioned. SUSPENSION SYSTEM: This will explain both the Hydraulic Suspension systems at the front and the leaf spring Suspension at the Rear. One of the hydraulic arrangements of Suspension mechanism is highlighted (with shock absorbers) and explained cut sectionally.BRAKING SYSTEM:

The Hydraulic or Air circuit Brakes. The movement of the Brake Shoes on operating the brake pedals can be seen in the area where the Brake drum is cut. The front and rear brakes will be operational. STEERING MECHANISM: The can be seen and included in the Steering wheel. Steering gear box and coupling of the same to the wheels will be shown by rotating the steering wheel, the operation of the steering system can be demonstrated. The entire system will be mounted on the chassis, and suitable mounting option with caster wheels will be provided for easy movability.Gas Tap, Regular

Description

Made of brass with superior black powder coating. Regular construction having lever handle with locking arrangement to ensure lever rotation does not go beyond 90°. Output nozzle having 4mm bore. Inlet 3/8 X 26. Flange diameter 50mm with two holes to fix on bench or any other surface with screws. Provided with adapter (6/8, 3.8mm bore) and corresponding nut (8mm bore). Designed to operate at pressure up to 2 psi (0. 14kg/cm2). Suitable for use with coal gas, natural gas and L.P.G.Particulars

Gas Tap, One Way Gas Tap, Two Way Gas Tap, Three Way Gas Tap, Four WayXTEMOS ELEMENT

AJAX PRODUCTS TABS LOAD MORE PAGINATION

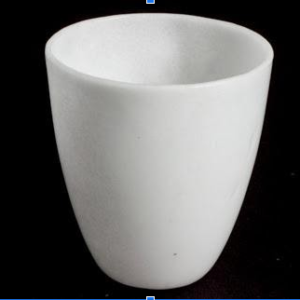

SILICA CRUCIBLE WITHOUT LID

PRODUCT DESCRIPTION

- Crucible is glazed inside and outside.

- Highly resistant to alkalis and hot temperatures

- 50ml capacity

- Outside diameter 55mm, 42mm height

- No lid includedSilica crucible is glazed inside and outside. Highly resistant to alkalis and hot temperature SIZES ARE: 15ML 25ML 50ML 80ML 100ML 150ML

SILICA CRUCIBLE TALL FORM Without Lid, Translucent

XTEMOS ELEMENT