XTEMOS ELEMENT

AJAX PRODUCTS TABS

Internally Expanding Mechanical Drum Brake System

Thermal Conductivity Of Metal Rod

The apparatus consists of a copper bar, which is heated at one end, a heat sink is provided at other end. The test section of bar is properly insulated and thermocouples are attached along the length of bar. Heat conducted through the section of bar is measured by heat collection in water-cooled heat sink. A panel comprising of controls and measurements is provided, which provides easy operation and sturdy mounting of unit.

SPECIFICATIONS:

1.Metal Bar – 25mm of adequate length, provided with 8 Thermocouples along the length, Band heater at one end and water-cooled heat sink at other end. Test portion of bar is insulated. 2.Instruments panel comprising of. Voltmeter … 1No. Ammeter … 1No. Dimmerstat 0-230v, 2A, capacity. Multichannel Digital temperature Indicator. 3.Measuring flask and stop clockSERVICES REQUIRED:

1.Bench area of 1.5m. x 1m. at working height. 2.230 v, AC, electric supply with earthing connection. 3.Water supply at the rate of 2 lit/mmRoots, Stems, Leaves

Description

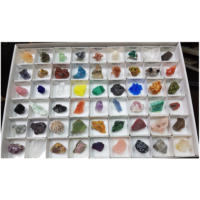

All Charts are made on PVC rexine, hand drawn, waterproof, in fast multicolours with a black background. Each chart is provided with rollers to hang on wall. Size 75×100 cm. T.S Dicot root T.S Monocot root T.S Dicot stem T.S Monocot stem T.S Dicot leaf T.S Monocot leaf Root modification Stem modification (Arial) Leaf modification T.S dicot stem secondary growth Vegetative propagation Artificial propagation Specialized stems Typical leaf showing parts Types of leaves Simple leaves Stipules Leaf venation Compound leaves Phyllotaxy T.S. Dicot root Leaf Lamina secondary growthSeparating Throttling Calorimeter

AIM

To find out dryness fraction of steam by combined separating and throttling calorimeter.

PRODUCT DETAILS

The steam passing out from separating calorimeter may still contain some water vapour , in it . in other words it may not be absolutely dry . again , in a throttling calorimeter steam after passing through the throttle valve must be superheated or at least dry saturated . this limits the extent of dryness fraction that can be reliably measured , depend up on the pressure of steam in the main steam pipe . if a sample of steam, which may be still wet after passing through the throttle valve i.e it will not be superheated . thus under this condition the throttling calorimeter fails to enable us in determining the value of dryness fraction of steam . to overcome this difficulties we make use of separating and throttling calorimeter . first the steam is passed through separating calorimeter where itlosses most of it’s moisture and becomes comparatively drier, it is than passed through the throttling calorimeter where super heating takes place with out changr of total heat . the temperature and pressure of steam after throttling are measured by using a thermometer and manometer respectively.DESCRIPTION

The set up consist of a separating and throttling calorimeter . a steam generator is provided at the base of the apparatus . a thermostat knob is provided at the front of apparatus to control the temperature inside the steam generator . steam from steam generator is passed from separating calorimeter where most of the water partical get separated from steam and then passed to throttling calorimeter where steam get superheated . after that superheated steam passed through heat exchanger to condense the steam.SAPARATING CALORIMETER

It consist of two concentric chamber , the inner chamber ,and the outer chamber . which communicates with each other through an opening at the top. As the steam discharge through the metal baskets ,which has a large number of holes , the water partical due to there heavier momentum get separated from the steam and collected in the chamber. The comparatively dry steam in the inner chamber moves up and than down aging through the annular space between the two chambers and enters the throttling calorimeter .THROTTLING CALORIMETER

It consist a narrow throat . pressure and temperature are measured by manometer and thermometer . the steam after throttling process passed through the heat exchanger and condensate is collected .UTILITIES REQURIED

1.WATER SUPPLY 3 lit/min (approx) 2.Drain 3.Electric supply : 1phase , 220 V A.C , 2Amp. 4.Steam table for calculation 5.Space required : 1.0 m X 1.0 mXTEMOS ELEMENT

AJAX PRODUCTS TABS SIMPLE

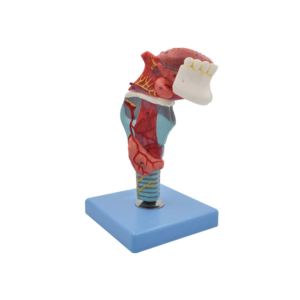

Human Tooth, Upper Triple Root In 2 Parts

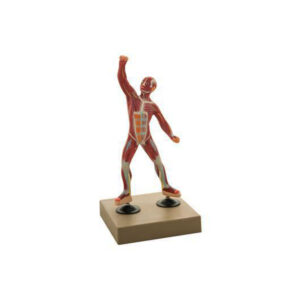

Muscle Figure

Mating Cage

XTEMOS ELEMENT

AJAX PRODUCTS TABS ALTERNATIVE

Fashion

Human Ear, Enlarged, 2 Parts

Gear Box Actual Cut Section

Gear Box – Actual Cut Section

The working of gear box is shown with the help of actual parts assembled on square iron pipe frame. All the necessary parts of gear box are shown in actual working form. This model helps the student to understand the working of the gear box very easily. It is specially made dissectible for demonstration purposes.

Acrylic Ray Optics Set

XTEMOS ELEMENT

AJAX PRODUCTS TABS ARROWS PAGINATION

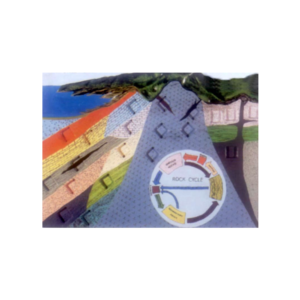

Rock Cycle Model

Vernier Transit Theodolite

Staining Box

XTEMOS ELEMENT

AJAX PRODUCTS TABS WITH ICONS

Cyclone IV FPGA Controller

FEATURES:

• Based on Altera family Cyclone IV, Device : EP4CE30 • One 34 pin header used for IPM Interface. - 16 PWM output - 8 capture inputs. • One 26 pin header ADC. - 4 channel 1MSPS ADC. - Total 8 channel using 2 Nos of ADC. - 12 bit resolution. - Input range -10V to 10V / -5V to 5V. • One 5 pin phoenix connector DAC - 4 channel DAC, 12 bit resolution. - Output range -10V to 10V / -5V to 5V. • 8 output Light Emitting Diodes (LEDs). • 8 input slide Switches. • 4 user push button switches. • 2-user limit switch. • 20 x 4 Alphanumeric LCD display. • On Board Isolated JTAG Programmer Compatible with QuartusII software. • Isolated USB (USB to Serial) interface. • 3 Nos of 20 pin header each have 16 IOs.Model of Dentition development

Resistor Set

Description

Consisting of six resisters of resistances with different current ratings. The resistors can be used in either the series or parallel mode. The resistors can be connected to any of the desired circuits through the safety sockets provided on the top of the kit for each resistor separately. Accuracy ± 5% . The specifications of each resistor are printed on the top panel of the kit. Mounted in moulded box.Volumetric Flask

We introduce our special quality Volumetric Flasks.

These Volumetric Flasks are blown in Polypropylene and are strong, unbreakable and have good contact clarity.

These autoclavable Volumetric Flasks are provided with screw caps to prevent leakage.

These Volumetric Flasks are economic as well.

Material : Polypropylene

| Particulars | Pack (Pcs) | |

|---|---|---|

| Volumetric Flask 25 ml | 6 | |

| Volumetric Flask 50 ml | 6 | |

| Volumetric Flask 100 ml | 6 | |

| Volumetric Flask 250 ml | 3 | |

| Volumetric Flask 500 ml | 3 | |

| Volumetric Flask 1000 ml | 2 |

XTEMOS ELEMENT

AJAX PRODUCTS TABS LOAD MORE PAGINATION

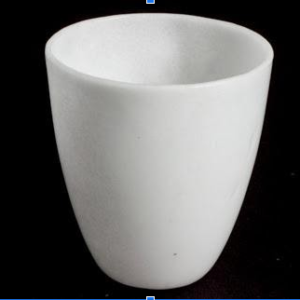

SILICA CRUCIBLE WITHOUT LID

PRODUCT DESCRIPTION

- Crucible is glazed inside and outside.

- Highly resistant to alkalis and hot temperatures

- 50ml capacity

- Outside diameter 55mm, 42mm height

- No lid includedSilica crucible is glazed inside and outside. Highly resistant to alkalis and hot temperature SIZES ARE: 15ML 25ML 50ML 80ML 100ML 150ML

SILICA CRUCIBLE TALL FORM Without Lid, Translucent

XTEMOS ELEMENT