XTEMOS ELEMENT

AJAX PRODUCTS TABS

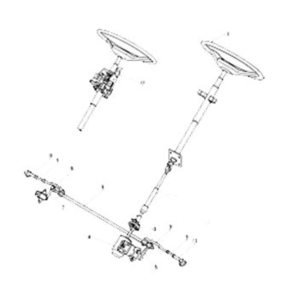

Manual Steering System

Steering System – Actual Working

Manual Steering System

The working of steering system is shown with the help of actual parts assembled on square iron pipe frame. All the necessary parts of steering system are shown in actual working form. This model helps the student to understand the working of the steering system very easily. It is specially made dissectible for demonstration purposes.

Autoclaves / Pressure Steam Sterilizers Superior

Specification

Superior quality & finish. All these autoclaves are made of 8 gauge aluminum. The drum is deep drawn. The lid is die casted. Locking of lid by 6 nuts with rubber gasket seal in between (no metal to metal seal). Two safety valves, pressure gauge, flexible metal tubing to exhaust air. Includes outer stand, inner tripod stand.Features

Equipped with two stages "over pressure" protection system incorporating a calibrated continuous bleeding Pressure stopcock and pressure release weight valve.Pressure Gauge

Colour coded pressure gauge showing internal chamber conditions during the cycle. Sterilization zone in green colour is shown from 15 psi to 20 psi (or 1.034 bar to 1.378 bar) which is equivalent to temperature of 121°c to 127°c. Dial size : 2.5". Dial show measurement in 2 units. (i) kg/cm2 (ii) lb/inch2 Full scale dial of pressure gauge is 0-30 lb/ inch2 or 0-2 kg/cm2 Caution zone in red colour. Equipped with steam release /control valve and flexible metal exhaust tube.| Capacity (Lt.) | Power | Size | Type |

|---|---|---|---|

| 21 Ltr | Electric | 300 x 300mm = 12” x 12” | Mirror Finish |

| 21 Ltr | Non Electric | 300 x 300mm = 12” x 12” | Mirror Finish |

| 27 Ltr | Electric | 300 x 380mm = 12” x 15” | Mirror Finish |

| 27 Ltr | Non Electric | 300 x 380mm = 12” x 15” | Mirror Finish |

| 37 Ltr | Electric | 350 x 380mm = 14"x15" | Mirror Finish |

| 37 Ltr | Non Electric | 350 x 380mm = 14"x15" | Mirror Finish |

XTEMOS ELEMENT

AJAX PRODUCTS TABS SIMPLE

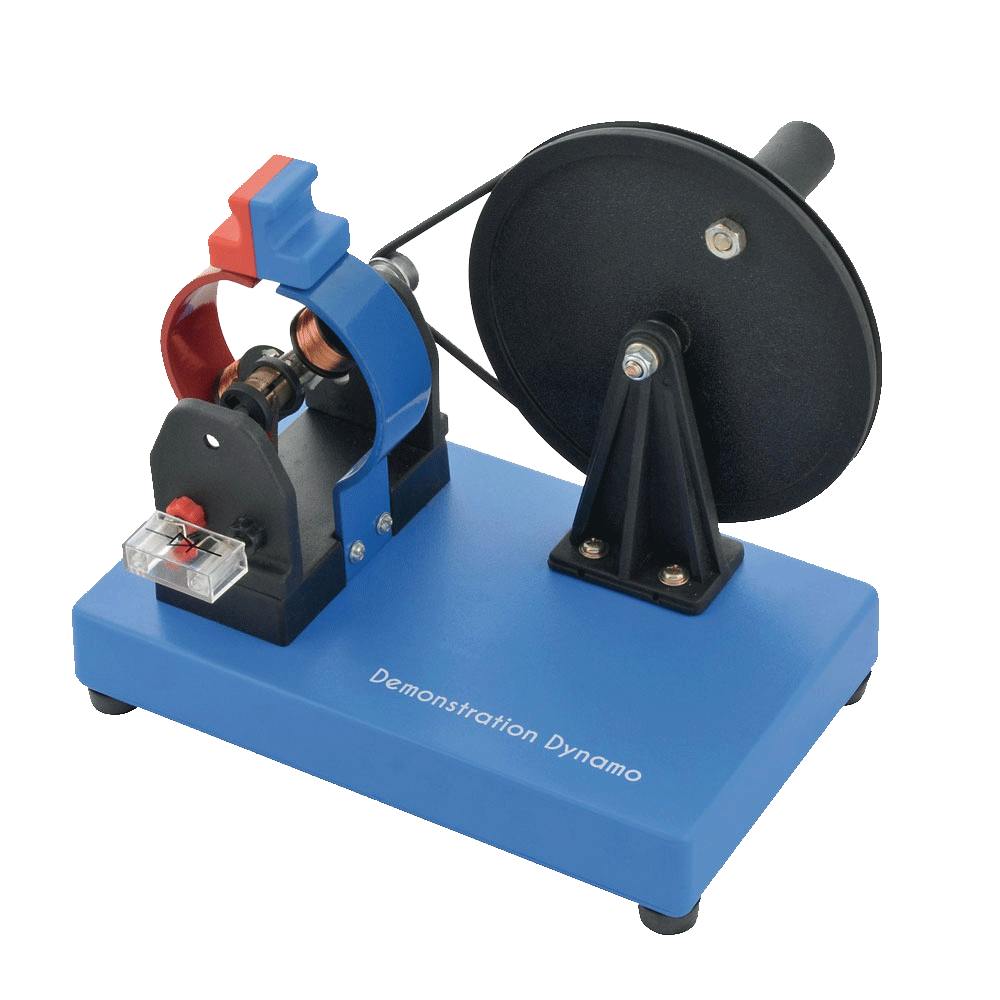

Stefan Boltzmans Apparatus

The Stefan Boltzmann constant is an important constant in heat transfer. The apparatus determines Stefan Boltzmann constant. The apparatus consists of a hemisphere surrounded by hot water. Hot water is obtained from a water-heating tank. When the blackened disc is inserted at the center of hemisphere, heat is transferred into the disc from hemisphere by radiation and its temperature begins to rise, and from temperature raise rate. (It is measured at the intervals of 5 sec.) Stefan Boltzmann constant is determined.

SPECIFICATIONS:

Water heating tank provided with electric immersion heater. Hemisphere made of copper sheet, 200mm. dia. Surrounded water jacket of 250mm. Dia. Test disc made of copper 20mm. dia. provided with thermocouple at the center. Multichannel digital temperature indicator 0-200 C with 0.1C least counts to measure the temperature of hemisphere and disc. Audible buzzer with timer to ring at every 5 seconds. A technical manual accompanies the unit.SERVICES REQUIRED:

1.Bench area of about 1m. x 05m. at working height. 2.230v, 15A, AC, electric supply with earthing connectionPrismatic Compass

Description

• Made of Aluminium/brass. • Size 100mm, 125 mm, 150 mm dia. • Complete in Case with Aluminium Telescopic/Rigid/Wooden Tripod. • Aluminium circle consist of a needle graduated to 30min (0.5) graduations. • Painted with water proof paints. • Carrying cases are made of Fibre with carrying straps. Least count 30'.Slip Creep Measurement Apparatus

The apparatus consists of a variable speed D.C. Motor, Driving pulley and Driven pulley of equal diameter. The pulleys are mounted on input shaft (Motor shaft) and output shaft. The driven pulley can slide on the base with bearing block to change initial tension in belt. Brake drum is mounted on output shaft helps to measure power output. The motor speed is varied by dimmerstat. A two channel RPM Indicator is provided to measure speeds of driven and driving pullies respectively.

Specifications:

1.D.C. Motor – 1 HP, 1500 RPM, variable speed. 2.Driving & Driven puilies of equal diameters. 3.Brake drum along with spring balance. 4.Fiat Belt of fixed length of following materials – (i)Fabric Belt (ii)Canvas Belt. (iii)Rubber Belt. 5.Belt tightening arrangement. 6.Speed Controller unit. 7.Two Channel digital RPM Indicator. 8.Stroboscope.Experimentation –

1. To measure co-efficient of friction between pulley material and different belt materials. 2. To measure power transmitted with varied belt tensions and plotting graph of (T1 – T2).Tension Characteristics. 3. To measure percentage slip at fixed belt tension by varying load on brake drum and plot graph of (T1-T2) Vs.percentage slip.i.e. Slip Characteristics. Finding a creep zone from graph. 4. To measure belt slip speed and observe the limiting value float at constant speed when the slip just starts.Service Required:

1.230 V.A.C. stabilized power supply 2.Space -. 1.5m x 1.5 m.XTEMOS ELEMENT

AJAX PRODUCTS TABS ALTERNATIVE

Fashion

Linear Expansion Apparatus, Micrometer Screw Form

Description

A 500 mm long metal rod is supported in a plated brass tube with three tubules for steam inlet, outlet and thermometer. The tube is mounted on a stand with an adjusting screw at one end and a micrometer screw reading to 0.01 mm on the other, with terminals for connecting a bell or galvanometer to indicate contact. With copper, brass and iron test rods but without thermometer.Digital Colony Counter

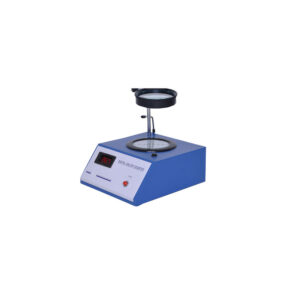

Description

Fitted with automatic 3 Digits LED Digital Display. Counting plate with illuminated standard wolf hugel ruling ensures clearly differentiated and sharply defined colonies. Each touch of making pencil in the petri dish increment the colony count by '1' and the glowing LED Display depicts the total colony count. Provided with a manual reset of digital display, ON/OFF Switch, counting plate, 100 mm. dia lens, cord and plug. To work on 220V A.C.XTEMOS ELEMENT

AJAX PRODUCTS TABS ARROWS PAGINATION

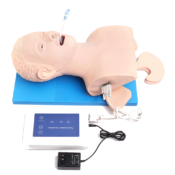

Advanced Surgical Suture Arm

Description

Interchangeable arterial and venous inserts within the fore arm allow creation of arteriovenous (AV) fistulas and placement of AV grafts, while a simulated healed fistula insert provides a platform on which hemodialysis exercises can be performed. An additional multi-layer insert in the bicep area can be used for incision and suture training exercises.Advanced Arterial Patient Training Arm Features:

Subcutaneous injection sites on the volar forearm and lateral upper arm Intra Muscular injection site on the upper arm Arterial system including the radial and brachial arteries Suture and incision sites on both the upper arm and forearm Hem dialysis site on the forearm Arterial and Venous insert for IV and blood draw exercises, AV anastomosis, and placement of AV grafts. This multi-layer surgical insert includes the skin, subcutaneous tissue, muscle, radial artery, and radial vein AV fistula insert that simulates a healed fistula for hem dialysis exercises. Multi-layer bicep insert that includes the skin, subcutaneous tissue, and muscle and allows incision and suturing exercises Durable skin that can be pierced in excess of 200 times with a 20 or 22 gauge needle Realistic tactile feedback for both surgical and arterial & venous stick exercises Adjustable heart rate and pulse strength simulating a heart rate from 10 BPM to 150BPM Cephalic (antecubital), Basilic, Radial, and Ulnar veins as well as the radial and brachial arteries for infusion and blood draw. Rotating arm allowing dorsal and volar access along the length of the arm. Varying vessel palpability to simulate collapsed or bulging vessels and ease of assembly. Latex-Free New proprietary materials replicate of skin, subcutaneous, and muscle layers at all surgical sites. Upgraded inserts, skins, and vessels for improved tactile feedback Micro pump embedded within the shoulder generates variable heart rates and pulse strength. Easy to replace plug-and-play inserts to allow quick change-out between procedures. Latex-free vessels with improved access for hassle-free replacement.Hydraulic Linear Actuation System Trainer with Labview Interfacing

Features

• This trainer helps to learn the characteristics of double acting cylinder namely direction, speed & force. • A Microcontroller ADC relay driver provided to actuate the cylinder. • Gear pump supplies the hydraulic fluid to double acting cylinder through direction control valve. • Pressure control valve controls the flow rate of fluid to cylinder. • Single phase induction motor drives the pump. • Control unit communicate with PC and controls the double acting cylinder using LabVIEWSoftwares. • Two proximity sensors are provided to indicate the position of the cylinder. • Load cell measures the force developed by the cylinder. • 5/2 Double Solenoid Valve directs the cylinder. • One tank is used to store the hydraulic fluid.Bottle Stand for 6 bottles

Pelton Wheel Turbine Test Setup

DESCRIPTION:

Pelton Wheel Turbine is only impulse water turbine now in common use named in honor of Sir L.A. Pelton (1829-1908) of California, USA. It is a tangential flow impulse turbine. The water strikes the buckets along the tangent of the runner. The energy available at the Inlet of the Turbine is only kinetic energy. The Pressure at the Inlet and Outlet of the atmospheric. This turbine is used for high heads. The Present Set-up consists of a runner. The buckets are mounted on the runner. The water is fed to the turbine, through SS nozzle with a SS spear, by means of Centrifugal Pump, tangentially to the runner. Row of water into turbine is regulated by adjusting the spear position by the help of a given hand wheel the runner is directly mounted on one end of a central SS shaft and other end is connected to a brake arrangement. The circular window of the turbine casing is providing with a transparent acrylic sheet for observation of flow on to the buckets. This runner assembly is supported by rigid MS structure. Load is applied to the turbine with the help of this brake dynamometer so that the efficiency of the turbine can be calculated. Pressure Gauge is fitted at the Inlet of the turbine to measure the total supply head to the turbine.EXPERIMENT:

1.To study the operation of a Pelton Wheel Turbine 2.To determine the Output Power of Pelton Wheel Turbine 3.To determine the Turbine EfficiencyUTILITIES REQUIRED:

● Water Supply and Drain.● Electricity 15 kW, 440V AC, Three Phase

TECHNICAL SPECIFICATIONS:

| MODEL | HM 111 (1.33 HP) | HM 111 (2 HP) | HM 111 (5 HP) |

| Output Power | 1.33 HP / 1 Kw | 2 HP / 1.5 Kw | 5 HP / 3.75 Kw |

| Discharge | 300 LPM (Approx.) | 400 LPM (Approx.) | 630 LPM (Approx.) |

| Supply Head | 25 m | 40 m | 45 m |

| Rope Brake Dynamometer | Dia 200 mm | Dia 200 mm | Dia 300 mm |

| Sump Tank | Capacity 150 Liters. | Capacity 200 Liters. | Capacity 300 Liters. |

| Water Circulation Centrifugal Pump | Capacity 5 HP, Three Phase | Capacity 7.5 HP, Three Phase | Capacity 15 HP, Three Phase |

| Speed | 1000 RPM (approx.) | ||

| Impeller | Material Brass, Bucket type | ||

| Nozzle | Material Stainless Steel/Mild Steel | ||

| Spear | Material Stainless Steel/Mild Steel | ||

| Discharge Measurement | Pitot Tube with Manometer | ||

| Control Panel | Star/Delta Starter, Mains Indicator, MCB for overload protection | ||

| The whole set-up is well designed and arranged in a good quality painted structure. | |||

XTEMOS ELEMENT

AJAX PRODUCTS TABS WITH ICONS

Soil Auger, Helical

CNC Mill Trainer1

CONTROLLER:

Type of Controller System : PLC based system under collaboration from tudor,uk Main Spindle Drive : D.C. Thyristor Drive, Inbuilt Safety X, Y and Z axis Drives : Stepper motor drive TTL Compatible Input to Stepper :Optically lsolated , motor drive TTL Compatible Interpolation : Linear, Circular parabolic Interpolation Code Used : G, M, S, T, F, I, K, M, F, Cycles : Circular Interpolation, Mirror, Pocket Milling Cycle Pocket & Helical Milling : Provided with Std Codes Real time tool path :with online 3D simulationTABLE:

Length x Width : 600 x 225 (approx.) Clamping Area : 450 x 160 (approx.) T Slots : 10mm slot width.MACHINE DETAILS:

Resolution : 5 micron(Standard) Distance from sindle :25-225mm(Nose to table top) Centerline to column :170mm Rapid Travel 700 mm/min Weight in kg : 950kg Dimension in mm : 1200 x 1200 x 1900 mmSPINDLE:

Spindle Speed : Continuous Variable Spindle power : 1.5 HP Inside Taper : ISO 30 Speed Range : 300 to 3000 RPMOcean Features Model

XTEMOS ELEMENT

AJAX PRODUCTS TABS LOAD MORE PAGINATION

SILICA CRUCIBLE WITHOUT LID

PRODUCT DESCRIPTION

- Crucible is glazed inside and outside.

- Highly resistant to alkalis and hot temperatures

- 50ml capacity

- Outside diameter 55mm, 42mm height

- No lid includedSilica crucible is glazed inside and outside. Highly resistant to alkalis and hot temperature SIZES ARE: 15ML 25ML 50ML 80ML 100ML 150ML

SILICA CRUCIBLE TALL FORM Without Lid, Translucent

XTEMOS ELEMENT