XTEMOS ELEMENT

AJAX PRODUCTS TABS

Ball & Ring GRAVESANDE

Mosquito Breeder

IoT Development System

The industrial networks are primarly concerned with Programmable Logic Controllers(PLC),Distributed Control Systems(DCS), Supervisory Control and Data Acquistion Systems(SCADA) any many other hetrogenous devices in the form of differnt applications. More over these devices are based on either wired or wireless communication protocols like Profinet, Profibus, MODbus, WiFi, Zigbee and Etc.

Specification:

• To impart the knowledge about Industrial IoTa the Students, We have designed a IIOT trainer kit, which have inter-quark chip based IoT Gateway. • This Gateway is a universal Gateway supports many different types of communication protocols such as wired and Wireless communication for industrial applications. • The IIoT Gateway connected with Siemens based Distributed Control System(DCS), Programmable Logic Controller(S7-1200, S7-1500) using S7-protocol and OPC UA. • The Intel centrino based powerful WiFi chip enables us to the access data via Mobile Application. • The Gateway can get the internet connectivity via Ethernet and WiFi also. • This Gateway can communicate with our own ingenious data acquisition system using RS485 BUS and RS232 Bus. • The USB based communication exchange the data between Zigbee co-coordinator and Gateway.Underground Mine Model

XTEMOS ELEMENT

AJAX PRODUCTS TABS SIMPLE

Calorimeter, Electric

Thermal Conductivity Of Insulating Powder

The apparatus consists of an insulating powder, which is enclosed in a cavity of two concentric spheres. The inner space of the inner sphere contains the mica heater. Input to the heater can be adjusted by the dimmerstat. The tappings on the surfaces of the inner sphere and outer sphere are used to find out the temperature difference between the spheres. This enables to find out the conductivity of powder.

Specifications:

1.Inner sphere dia. 100mm and outer sphere dia. 200mm. 2.Mica heater two heat the inner sphere surface. 3.Ten thermocouple tappings in the test section. 4.Plaster of Paris / asbestos powder in the test section. 5.Panel comprises of a)Voltmeter and ammeter b)Dimmerstat c)Temperature indicatorServices required:

1.220v stabilized single-phase supply. 2.Floor surface 1m x 0.5m at working height.Peritoneal Dialysis Simulator

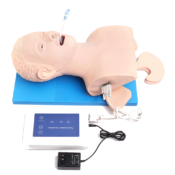

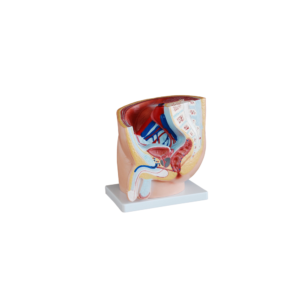

Description

For Continuous Ambulatory Peritoneal Dialysis. Designed to introduce patients, students, and nurses to the essentials of CAPD procedures and care. The realistic torso offers a realistic method to demonstrate and practice peritoneal dialysis. Success with CAPD is dependent on the patient’s following dialysis procedures with extreme care. This Life/form simulator gives the patient an opportunity to gain the confidence necessary for prolonged success with CAPD. Complete with indwelling Tenckh off catheter in a hard carry case. Dialysis materials not included.Sterling Engine Working Model

The Stirling engine was invented by Robert Stirling, a Scottish minister, in 1816. A Stirling engine is a heat engine that operates by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work.

XTEMOS ELEMENT

AJAX PRODUCTS TABS ALTERNATIVE

Fashion

Block, Glass

Distributed Control System

A powerful, modular & upgradable DCS has been designed and configured based on Siemens controller SIMATIC PCS7 ASRTX (Micro Box). Distributed I/O system ET200M can be provided for field automation. The distributed I/O can be connected via Profibus, Communication. DCS consists of controller, Power supply unit, distributed I/O, Digital Input and Output modules, Analog Input and Output module. a Demo Panel and Simatic PCS7 V9.0 Software.

DCS Controller

• Make : SIEMENS. • Controller : SIMATIC PCS 7 AS RTX BOX. • Profibus Communication done via CP5611 onboard. • Transmission Rate of Profibus cable is 12 Mbit/s. • 2 x GBIT & RJ45 LAN • Core 17-3517 Processor 1.7GHz, 4GB DDR3 RAM, SSD 80GB, 4xUSB V3.0 • Mouse and Keyboard • Windows7 • Win AC RTX 2010 software controllerDistributed I/O station ET200M

• Support HART, PROFIBUS, Foundation Field bus. • 16 No’s of digital Inputs with 24V DC. • 16 No’s of digital Outputs with 24V DC. • 8 channels of Analog Inputs with 4-20mA. • 8 channels of Analog Outputs with 4-20mA. • 24VDC /10A inbuilt power supply.XTEMOS ELEMENT

AJAX PRODUCTS TABS ARROWS PAGINATION

Mirror Stereoscope

Stop Clock, Mechanical

Large Rectangular Transparent Tank

Separating Throttling Calorimeter

AIM

To find out dryness fraction of steam by combined separating and throttling calorimeter.

PRODUCT DETAILS

The steam passing out from separating calorimeter may still contain some water vapour , in it . in other words it may not be absolutely dry . again , in a throttling calorimeter steam after passing through the throttle valve must be superheated or at least dry saturated . this limits the extent of dryness fraction that can be reliably measured , depend up on the pressure of steam in the main steam pipe . if a sample of steam, which may be still wet after passing through the throttle valve i.e it will not be superheated . thus under this condition the throttling calorimeter fails to enable us in determining the value of dryness fraction of steam . to overcome this difficulties we make use of separating and throttling calorimeter . first the steam is passed through separating calorimeter where itlosses most of it’s moisture and becomes comparatively drier, it is than passed through the throttling calorimeter where super heating takes place with out changr of total heat . the temperature and pressure of steam after throttling are measured by using a thermometer and manometer respectively.DESCRIPTION

The set up consist of a separating and throttling calorimeter . a steam generator is provided at the base of the apparatus . a thermostat knob is provided at the front of apparatus to control the temperature inside the steam generator . steam from steam generator is passed from separating calorimeter where most of the water partical get separated from steam and then passed to throttling calorimeter where steam get superheated . after that superheated steam passed through heat exchanger to condense the steam.SAPARATING CALORIMETER

It consist of two concentric chamber , the inner chamber ,and the outer chamber . which communicates with each other through an opening at the top. As the steam discharge through the metal baskets ,which has a large number of holes , the water partical due to there heavier momentum get separated from the steam and collected in the chamber. The comparatively dry steam in the inner chamber moves up and than down aging through the annular space between the two chambers and enters the throttling calorimeter .THROTTLING CALORIMETER

It consist a narrow throat . pressure and temperature are measured by manometer and thermometer . the steam after throttling process passed through the heat exchanger and condensate is collected .UTILITIES REQURIED

1.WATER SUPPLY 3 lit/min (approx) 2.Drain 3.Electric supply : 1phase , 220 V A.C , 2Amp. 4.Steam table for calculation 5.Space required : 1.0 m X 1.0 mXTEMOS ELEMENT

AJAX PRODUCTS TABS WITH ICONS

Xilinx Spartan 3E FPGA Trainer Kit

Specification

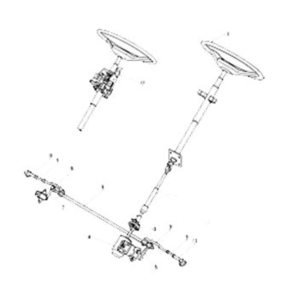

• XC3S250E - 4PQ208C / XC3S500E-4PQ208C • 16 Nos. of digital input using slide switches with LED indication • 16Nos. Of digital outputs using discrete LEDs • 16 x 2 LCD is provided for display the text message. • One Reset Switch • One switch is provided for giving manual clock • FPGA configuration through - JTAG Port - On board Flash Prom XCF02S • Total 158 I/O pins : 124 pins used for integrating peripherals like LED, Switches etc., balance pins available to user in 20 pin • header (3.3V compatible) • 1No of 26pin header to interface VLIM cards like Traffic Light Controller (5V compatible) • On board programmable PLL oscillator from 1 MHz to 100 MHz using jumpers • 4 Nos of 7 segment LED display • One relay and Buzzer provided. • Stepper & DC motor Driver provided. • 4 * 4 matrix key provided • Housed in a sleek plastic cabinet with built in SMPS 5V/2A. • Compatible with Xilinx ISE Design Suite WebPACK Software. • On board USB to JTAG is available for configure FPGA (Supports only with Vi JTAG 5.0 Software)Manual Steering System

Steering System – Actual Working

Manual Steering System

The working of steering system is shown with the help of actual parts assembled on square iron pipe frame. All the necessary parts of steering system are shown in actual working form. This model helps the student to understand the working of the steering system very easily. It is specially made dissectible for demonstration purposes.

XTEMOS ELEMENT

AJAX PRODUCTS TABS LOAD MORE PAGINATION

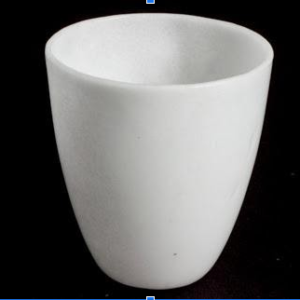

SILICA CRUCIBLE WITHOUT LID

PRODUCT DESCRIPTION

- Crucible is glazed inside and outside.

- Highly resistant to alkalis and hot temperatures

- 50ml capacity

- Outside diameter 55mm, 42mm height

- No lid includedSilica crucible is glazed inside and outside. Highly resistant to alkalis and hot temperature SIZES ARE: 15ML 25ML 50ML 80ML 100ML 150ML

SILICA CRUCIBLE TALL FORM Without Lid, Translucent

XTEMOS ELEMENT